- 首页

- 关于我们

- 商品橱窗

- BA/EP 不锈钢管 [13]

- 不锈钢BA管, 不锈钢光辉退火管, 无缝不锈钢管(Bright Annealed Tube / Pipe )

- 不锈钢EP管, 不锈钢电解抛光管 (Stainless Steel ElectroPolished Tube / Pipe )

- 卫生级不锈钢管, 食品级不锈钢管, 优耐特不锈钢管Rath/United

- 不锈钢冷锻BA管, 无缝不锈钢精密管 有缝不锈钢精抽管, ®DTI Cold Forged Bright Annealed Stainless Steel Tubing/不锈钢冷锻ba管

- 半无缝 BA 管 ( Bright Annealed Semi Seamless Stainless Steel Tube / Pipe)/BA 半无缝管

- 不锈钢盘管, BA/EP不锈钢卷管, 不锈钢卷形管, 软态不锈钢管(BA/EP Coiled Stainless Steel Tubing), Level Wound Coil Stainless Steel Tube, KUZE / Handy Tube Standard

- 无缝钢管, 不锈钢无缝管, 无缝不锈钢管, BA管, EP管(®DTI Cold Forged Bright Annealed Stainless Steel Tubing/Pipe)

- 无缝管, 不锈钢无缝管, 无缝不锈钢管(®DTI Cold Forged Bright Annealed Stainless Steel Tubing/Pipe)

- 热交换管 (Heat Exchanger Tube), 不锈钢换热管, 不锈钢无缝热交换管

- 精密不锈钢管, 小口径不锈钢管 ( Small Diameter Stainless Steel Tube / Pipe) / Teshima /Kyoto Seiken Precision Stainless Steel Tubing

- 高洁净气体管路,/ 高纯度气体管线, High Purity Gas Fittings/Swagelok Parker Stainless Steel Ultra High purity Fittings

- KUZE 不锈钢BA/EP管, 电解抛光管(Stainless Steel ElectroPolished Tube / Pipe ) Kuze / Rath / United Standards

- 气压缸不锈钢管,精密冷抽不锈钢气压缸管 (Pneumatic Cylinder Stainless Steel Tube, Air Cylinder Tube/ Pipe)

- 真空波纹管/真空软管 [21]

- 真空波纹管, 不锈钢真空软管(Stainless Steel Vacuum Bellows) / 不锈钢波纹管

- 不锈钢软管, 不锈钢伸缩接头, 不锈钢防震接头

- 超级波纹管, 不锈钢超级波纹管 (Super Bellows)

- 无缝不锈钢波纹管 (Seamless Metal Bellows)

- 真空软管, 真空波纹管 (Stainless Steel KF Vacuum Bellows)

- ISO真空软管, ISO真空伸缩软管(Stainless Steel ISO Vacuum Bellows)

- CF 真空软管, 不锈钢真空波纹管(Stainless Steel CF Vacuum Bellows)

- 焊接波纹管, 焊接式波纹管, 真空波纹软管(Metal Welded Bellows)

- 铁弗龙波纹管(Teflon Bellows), PTFE Bellows真空软管, Teflon真空软管/ Parker

- 不锈钢波状管(Corrugated Stainless Steel Tubing JWWA G119)/不锈钢波浪管(波纹管)

- 波纹管连轴器, 不锈钢波纹管联轴器, 不锈钢波纹管机械轴封(Bellows Mechanical Seal)

- 磁流体轴封, 磁性流体轴封, 真空磁流体机械轴封, 真空旋转导入(Ferrofluid Seals)/Vacuum Rotary Feedthrough

- 真空波纹管, 液压成型波纹管(Formed Bellows/Hydro Formed Bellows 成型波纹管)

- 真空伸缩接头, 真空伸缩管, 防震软管 Expansion Joint/Bellows Expansion Joint/Metal Hose/Stainless Steel Flexible Tubing

- 小口径不锈钢软管, 小口径真空波纹管, 高纯度气体不锈钢软管( Convoluted Flexible Tubing / Metal Hose / Flexible Stainless Steel Hose)

- 焊接波纹管, 焊接式波纹管, 边缘焊接式波纹管, Edge Welded Bellows / Vacuum Bellows/ Mewasa Type

- 消防软管, 消防撒水软管, 不锈钢消防洒水软管(Flexible Sprinkler Hose)

- 涡轮增压器排油管,不锈钢涡轮回油管, Turbo Charger Oil Drain Tube, Detroit Diesel Turbo Charger Oil Drain Pipe, Detroit Diesel Flex Stainless Steel Pipe

- 废气再循环管, 不锈钢EGR 管, Exhaust Gas Recirculation Tube, EGR Tube, EGR pipe

- 空气喷射歧管,不锈钢空气喷射歧管,二次空气喷射反应管, Secondary Air Injection Tube, AI Tube, Air Tube

- 不锈钢涡轮供油管,Turbo Oil Feed Tube, Turbo Charger Oil Feed Line, Detroit Diesel Flex Stainless Steel Pipe,

- 真空零组件 [50]

- 真空软管, 真空压缩软管(Stainless Steel KF Vacuum Bellows)

- 超级波纹管(Super Bellows)

- 不锈钢软管, 不锈钢伸缩接头, 不锈钢防震接头

- 真空波纹管 (Stainless Steel Vacuum Bellows), 不锈钢波纹管

- ISO真空波纹管, 真空伸缩软管, 真空蛇腹管(Stainless Steel ISO Vacuum Bellows/Bellow)

- 真空波纹管/ 不锈钢 CF 真空软管(Stainless Steel CF Vacuum Bellows)

- 无缝不锈钢波纹管 (Seamless Metal Bellows)

- 波纹管联轴器, 不锈钢波纹管连轴器(Bellows Coupling), Flexible Shaft Coupling

- 焊接波纹管, 焊接型波纹管, 边缘焊接波纹管, 真空波纹软管, 金属波纹管(Metal Welded Bellows)

- 铁弗龙波纹管(Teflon Bellows), Teflon Bellows 软管, Teflon真空软管/ Parker

- 真空角阀(Vacuum Angle Bellows Valve), 真空阀门(Bellows Sealed Vacuum Valves)

- 真空隔膜阀, 真空膜片阀(Vacuum Diaphragm Valve)

- 真空阀, 高真空阀, 超高真空阀(Stainless Steel Vacuum Valves)/真空阀门

- 真空球阀, 真空球塞阀(Vacuum Ball Valve)

- 真空蝶阀(Vacuum Butterfly Valve)

- 真空逆止阀, 真空止回阀, 不锈钢真空逆止阀 (Vacuum Check Valve)

- Swagelok 管件, Swagelok接头, Swagelok阀门 SWG lsf (Swagelok Valve Tube Fittings)

- 真空管件(Stainless Steel Vacuum Fittings), 真空零件(Vacuum Components), 真空零组件

- 真空视窗(Vacuum Sight Glass), 真空视窗玻璃(Vacuum Viewport)/真空观测器

- CGA DISS 接头, 钢瓶管件, 钢瓶接头 Cylinder Connections/Fittings/Adapter

- 真空导入, 真空导引, 真空馈通(Vacuum Feedthrough)/Vacuum Rotary Feedthroughs

- 真空管件(Stainless Steel Vacuum Fittings - KF Flange)

- 真空零件, 真空零组件 (Vacuum Components)

- KF 真空中心圈(KF Centering ), 滤网中心圈(Mesh Centering)

- 全氟化O Ring, FFKM O RINGS, 全氟化O型环, 全氟化O型橡胶圈, Perfluoroelastomer Morisei kako/Kalrez/Parker/NOK/Chemraz/日本制O型环

- ISO中心圈, 不锈钢 ISO 真空中心圈(Stainless Steel ISO Vacuum Centering Ring)

- 真空法兰, 高真空法兰, CF真空法兰 (High Vacuum Flanges)

- ISO真空法兰, 不锈钢 ISO 真空法兰衬套(ISO Vacuum Flange)

- 不锈钢 CF 真空法兰(Stainless Steel CF Vacuum Flange)

- 真空元件 (Vacuum Components)

- 真空管件, 真空管配件(Stainless Steel KF Vacuum Fittings)

- 真空管束, 真空管夹/ (Vacuum Clamp)/ KF Stainless Steel Vacuum Clamp/Heata Clamp

- 真空配管, 真空管路, 真空配管规格 (NW/KF/ISO/CF/VG/VF)

- ISO 真空转接头(Stainless Steel ISO Tube Adaptor)

- CF 真空法兰管件(Stainless Steel CF Flange Tubing)

- 不锈钢 CF 真空转接头(Stainless Steel CF Tube Adaptor)

- VCR 管件, VCR接头, VCR阀门, 气体管件 ( VCR Fittings / VCR Couplings Parker / VCR Micro Fittings)

- 金属波纹管, 真空蛇腹管 Metal Bellows

- 真空腔体, 不锈钢真空腔体, 不锈钢 VACUUM CHAMBER

- 食品级软管, 铁氟龙管, Teflon 软管(PTFE/PFA )/ Unigasket/ US Hose/ Teflon 管

- 锻造衬套, 金属法兰管端, 自动焊接法兰衬套/管节(Auto Welding Stub End)

- 客制化真空管件, 真空级订制管件,真空预制管道 (Custom Vacuum Fittings), Custom Made Vacuum Fittings

- 真空闸阀, 真空插板阀 (Vacuum Gate Valves/Vacuum Bellows valves)

- 真空过滤器, 真空阱, 真空陷阱 (Vacuum Traps/ Vacuum Foreline Traps/ Vacuum Filter)

- 真空帮浦维修, 真空泵浦配管零件 (Vacuum Pumps / Alcatel / Balzers / Dresser / Edwards / Hyvac / Kinney / Leybold / Orion / Pfeiffer / Stokes / Varian / Welch)

- KF真空法兰,高真空法兰 (KF Vacuum Flanges)

- VG真空法兰,VF真空法兰,高真空法兰 (VG/VF Vacuum Flanges)

- 三菱O型环, 密封圈, 垫片(MITSUBISHI SEAL, PACKING, GASKET, O Ring / Kalrez/ Parker/ NOK/Chemraz/ 日本制O型环

- NICHIAS垫片,TOMBO 垫片, Gaskets, Packing, O Rings, PTFE垫片, TEFLON垫片, FFKM O RINGS, 全氟化O型环, 全氟化O型橡胶圈

- 真空消音器,真空帮浦消音器,真空泵消音器 ,Vacuum Silencer, Vacuum Exhaust Silencer, Vacuum Pump Silencer, Edwards Standard

- 卫生级管件 [19]

- 不锈钢EP管, 不锈钢电解抛光管(Stainless Steel ElectroPolished Tube / Pipe ) Kuze / Rath / United Standards

- 不锈钢BA管, 不锈钢光辉退火管(Stainless Steel Bright Annealed Tube / Pipe )

- 生技制药管件(Stainless Steel Orbital Welding Fitting)

- EP管件(Electropolished Fittings), 电解抛光管件

- 生技制药夹式管件(Stainless Steel Tri - Clamp Fitting)

- 卫生级隔膜阀, 生技制药隔膜阀, 不锈钢隔膜阀(BPE Diaphragm Valve Ohno)

- 冷锻BA管, ®DTI Cold Forged Bright Annealed Stainless Steel Tubing, 不锈钢冷锻ba管

- 半无缝 BA 管 ( Bright Annealed Semi Seamless Stainless Steel Tube / Pipe)/ Seam Integrated Tubes

- 卫生级不锈钢管, 不锈钢卫生管(BPE-TUBE)

- BA/EP不锈钢卷管, 不锈钢卷形管 (BA/EP Coiled Stainless Steel Tubing)

- 不锈钢热交换管(Heat Exchanger Tube), 不锈钢热交换管, 无缝热交换管, 换热管

- 卫生级管帽, 不锈钢管帽, 不锈钢端板, 食品级管帽 (Sanitary Weld Cap)

- 锻造衬套, 金属法兰管端, 自动焊接法兰衬套/管节(Auto Welding Stub End)

- 卫生级滤网垫片, 食品级滤网胶垫/Mesh Screen Gaskets/ BPE Tri-Clamp Mesh Screen Gaskets

- 客制化卫生级管件, 卫生级订制管件,卫生级预制管路 (Custom Sanitary Fittings), Custom Made Hygienic Fittings

- 螺盖旋转瓶接头, 转瓶接头/零件 Vent Port Assembly/Spinner Flask Accessory/Corning

- 卫生级接头, 卫生级夹式接头 (Sanitary Ferrule / Hygienic Clamp Union)

- 卫生级由任接头, 卫生级由令接头 (Sanitary Union / Hygienic Union)

- 双扣式快速接头,双臂式快速接头,不锈钢大流量快速接头 (Camlock Couplings, Pixon Camlock Fittings, Camlock Quick Disconnect Couplings)

- 食品卫生级帮浦 [11]

- 卫生食品级转子帮浦, 卫生级转子泵浦(Sanitary Lobe Rotor Pumps)/Sanitary Rotary Pumps/Waukesha/Nakakin

- 卫生级泵浦, 卫生级离心泵浦 (Osaka Sanitary Centrifugal Pumps Types)

- 食品卫生级螺旋帮浦, 高黏度泵浦, 定量帮浦(Sanitary Progressive Cavity Pumps) / Mohno Pump

- 粉末溶解机, 卫生级粉末溶解帮浦, 食品级粉末溶解泵浦 ( Sanitary Powder Mixer Pump)

- 卫生级乳化帮浦, 食品级均质泵浦, 分散帮浦, 剪力泵浦(Sanitary Shear Blender Pump Fristam)

- 食品卫生级自吸式帮浦/泵浦(Iwai Kikai Kogyo Sanitary Self-priming Pumps Type)

- 卫生级高压离心帮浦, 卫生级离心泵浦(Sanitary High Pressure Centrifugal Pumps)/Fristam/ C100/C114/C216/C218/C328/CSF

- 食品级 Sine 帮浦, 卫生级泵浦(Sanitary Masosine Pump)/Jann Shin Disco/Shin Yuung Shuhn Machinery

- NAKAKIN 卫生食品级转子帮浦/泵浦(NAKAKIN Sanitary Lobe Rotor Pumps)/Sanitary Rotary Pumps

- Waukesha 卫生食品级转子帮浦/泵浦(Waukesha Sanitary Lobe Rotor Pumps)/Sanitary Rotary Pumps

- Osaka 卫生级离心帮浦, 卫生级泵浦(Osaka Sanitary Centrifugal Pumps) SE

- 工程及设备 [32]

- 卫生级过滤器, 食品级过滤器(Cone mill Screen)/Sanitary Strainer

- 卫生级桶式过滤器, 卫生级双桶式过滤器, 卫生级过滤桶 (Sanitary Basket Strainer/Filter )

- 扩散焊接机, 扩散焊接代工, 真空扩散接合设备, 扩散焊接炉 Diffusion Bonding Furnaces / PVA Tepla Type

- 不锈钢压力桶, 不锈钢加压容器, 不锈钢保压桶, 卫生级桶槽 (Stainless Steel Pressure Tank / Unicontrols / Nakakin)

- 卫生级软管, 食品级软管(Sanitary Food Grade Hose)

- 无菌空气过滤器, 卫生级桶槽呼吸阀 (Aseptic Air Vent Filter) Millipore CWVT L10 01

- 卫生级壳管式热交换器, 食品级壳管式热交换器(TEMA Tubular Heat Exchanger)

- 卫生级管式热交换器, 卫生食品级管式热交换器(Tubular Heat Exchanger)

- 板式热交换器, 卫生食品级板式热交换器(Heat-Exchanger)/Alfa Laval/APV/GEA/Hisaka/IWAI/Sondex

- 食品级软管,卫生食品级软管(Novaflex Food Grade Hose 3A Toyox )

- 卫生级喷球, 不锈钢喷球, CIP清洗球(Stainless Steel CIP Spray Ball)

- 不锈钢人孔, 卫生级桶槽人孔(Stainless Steel Manways)

- 卫生级压力表, 食品级隔膜式压力表, 均质机压力表, 卫生级温度表(Sanitary Pressure Gauge/Thermometer)

- 静态混合器, 静态混合管, 食品级静态混合器, 卫生级静态混合管(Static Mixer )/ Noritake Type

- 卫生级排气阀, 食品级排气阀(Sanitary Air Relief Valve)

- 法兰衬套, 不锈钢衬套, 金属法兰管端, 不锈钢锻造管端 (Stainless Steel Stub End / Lap Joint)

- 热水产生器(Mixers), 蒸气混合器

- 不锈钢筛网, 不锈钢标准筛网 (Test Stainless Steel Sieving)

- 卫生级配管工程, 自动焊接, 阀串(,Orbital Welding Services & Valve Units)

- 分歧管(Manifold Tubing), 管路预制工程

- Airfloat Air Bearing / Align, 气浮轴承, 空气轴承, 气浮平台/ 气浮输送台

- 自动焊接法兰, 轨道焊接法兰(Orbit Welding Flange/Auto Welding Flange)

- 卫生级配管, 真空配管, 生技配管工程, BA/EP 配管工程

- 雷射焊接加工设备

- BA炉, 光辉炉, 光辉退火炉, 不锈钢光辉炉(Bright Annealing Furnace)

- CIP系统(CIP/SIP), CSF, JEC, Inoxpa, Topline

- 纯蒸气产生器(Pure Steam Generators)

- 注射水设备(WFI:Single and Multiple effect)

- 材质分析仪(Spectrum Analysis Machine)

- 锥型整粒机, 粉碎整粒机 ( Cone Mill Grinder)/ Kemutec CM-1/CM-5/CM-7

- 管端加工机(Tube End Facing Machine)

- Alfagomma 软管, Alfagomma 工业软管/橡胶软管 (Alfagomma Rubber Hose FDA)

- 食品卫生级阀门 [27]

- 卫生级气动隔膜阀, 食品级气动隔膜阀(Sanitary Aseptic Pneumatic Diaphragm Valve Gemu Saunders Crane)

- 卫生级隔膜阀, 生技无菌手动隔膜阀, 卫生级膜片阀(Sanitary Aseptic Manual Diaphragm Gemu Saunders Crane Ohno)

- 无菌桶底隔膜阀, 卫生食品级桶底隔膜阀(Sanitary Aseptic Tank Buttom Diaphragm Valve Gemu Saunders Crane ITT)

- 卫生级三通隔膜阀, 生技无菌T 型隔膜阀, 卫生级膜片阀(Sanitary Aseptic 3 way Diaphragm Hygienic Gemu Saunders Crane)

- 无菌阀, 无菌气动阀(Sanitary Aseptic Valve ) , F型无菌手动阀/L,T,F型 Iwai/Toyo/Izumi

- 卫生级无菌阀, 无菌手动阀(Aseptic Stainless Steel Bellows Diaphragm Valve)/Iwai/Toyo/Izumi

- 卫生级气动蝶阀(Sanitary Pneumatic Butterfly Valve Litai)

- 卫生级蝶阀(Sanitary Butterfly Valve K. Young)

- 卫生级气动球阀(Sanitary Pneumatic Ball Valve Litai)

- 卫生级球阀, 食品级球阀 (Sanitary Ball Valve)

- 卫生级气动F型阀(Osaka Sanitary Type Pneumatic Control F Type Divert Valve)

- 卫生级气动L型阀(Pneumatic Control L Type Divert Valve)

- 卫生级排气阀, 食品级排气阀(Sanitary Air Relief Valve)

- 卫生级吹气阀, 食品级吹气阀(Sanitary Air Blow Valve)

- 卫生级取样阀, 无菌取样阀, 卫生级隔膜阀(Sanitary Aseptic Sample Valve )

- 卫生级充填阀, 食品级充填阀(Sanitary Heishin Filling Valve) FV2/FV3

- 卫生级波纹管阀, 无菌波纹管阀 Sanitary Bellows Valve (Ohno/Iwai/Izumi)

- 卫生级波纹管阀门 (Aseptic Bellows Diaphragm Valve)

- 大口径卫生级隔膜阀, 大尺寸卫生级隔膜阀 ( Large Diameter Hygienic Diaphragm Valve)

- 卫生级减压阀, 卫生级调压阀, 卫生级安全阀 Hygienic Relief Valve/Sanitary Safety Valve/Pressure Relief Valve/Goetze/Niezgodka

- 卫生级取样阀, 无菌取样阀 (Aseptic Sampling Valve/Hygienic Sampling Valve/Bio-Components/Bioengineering/B.Braun/NBS)

- 卫生级防混阀, 卫生级双座阀, 卫生级防混双座阀 ( Sanitary Mix Proof Double Seat Valve)

- 大口径卫生级蝶阀, 大尺寸食品级蝶阀 ( Large Diameter Hygienic Butterfly Valve )

- Osaka 卫生级球阀, 食品级球阀 (Osaka Sanitary Ball Valve)

- Osaka/ Top Line 卫生级考克阀,食品级考克阀,卫生级旋塞阀 (Osaka/ Top Line Sanitary Plug Valve)

- 卫生级逆止阀,卫生级止回阀,不锈钢食品级逆止阀 (Sanitary Check Valve)

- Osaka 卫生级气动阀, 食品级气动阀 (Osaka Sanitary Pneumatic Valve)

- 磷化铟晶圆( InP Wafer) [9]

- 真空管件/真空阀门 [16]

- 真空法兰, 高真空法兰, CF真空法兰 (High Vacuum Flanges)

- 真空接头, 真空快速接头, 真空旋转接头 (Vacuum Quick Disconnect / Vacuum Gauge Seal Port / Vacuum Quick Connect)

- 真空破坏阀, 破真空阀, 真空破坏器 (Up To Air Valve / Vacuum Breaker Valve / Vacuum Leak Port)

- 真空转接头, 真空法兰转接头, 真空配管转接头 (Vacuum Hybrid Adapter / Vacuum fitting To Flanges)

- 高纯度气体配管, 气体管路定制(Gas Delivery Product / High Purity Gas Delivery Tube Assembly)

- 不锈钢真空管夹, 不锈钢真空管束 (Vacuum Stainless Steel Clamp) / KF Hinged Clamp/Bulkhead Clamps)

- 森清化工O-Ring,森清化工 O型环, 日本O型橡胶圈, Morisei Kako O Ring /Kalrez/Parker/NOK/Chemraz/日本制O型环

- 真空阀门, 真空阀件, 真空角阀, 真空闸阀 (Vacuum Bellows Valve)

- 真空球阀, 真空球塞阀(Vacuum Ball Valves)

- 真空隔膜阀, 真空膜片阀, 真空隔膜调压阀 (Vacuum Diaphragm Valves)

- 真空蝶阀 (Vacuum Butterfly Valves)

- 真空阀, 高真空阀, 超高真空阀, 真空气动阀

- 地板阀, 真空墙阀, 吸尘插座(Vacuum Floor Inlet Valves)

- 焊接波纹管, 焊接式波纹管, 边缘焊接式波纹管, Edge Welded Bellows / Vacuum Bellows/ Mewasa Type

- 真空气动阀, 真空自动阀(Vacuum Electro Pneumatic Valve)

- 电磁不锈钢,日本磁性不锈钢,电磁阀铁芯材料,软磁合金 (Tohoku Steel Electromagnetic Stainless Steel)

- BA/EP 不锈钢管 [13]

- 服务

- 新闻

- 技术

- 制程

- 磷化铟晶圆

- 联系我们

商品

卫生级高压离心帮浦, 卫生级离心泵浦(Sanitary High Pressure Centrifugal Pumps)/Fristam/ C100/C114/C216/C218/C328/CSF

商品型号: SANITARY HIGH PRESSURE PUMPS

食品卫生级高压离心帮浦/泵浦

Sanitary High Pressure Centrifugal Pumps

CSM SERIES

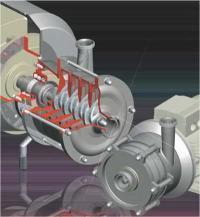

The CSM Series has been developed using the CS Series modular design concept. CSM pumps have multiple impellers, which can generate high discharge pressures. Large bearings support the pump shaft to provide both reliable operation on arduous duties and the convenience of being able to use standard IEC frame motors.

Flow rates up to 50 m³/h and heads up to 150 m (15 bar) can be achieved.

CSM pumps have been designed for high system pressure up to 40 bar.

The wetted parts are CF-3M/AISI 316L, the major components are investment cast and electro polished. Pump connections conforming to most international standard are available, as are other options.

卫生级帮浦性能曲线规格表

When properly sizing a pump, we need to know:

⇒ Product ⇒ Specific Gravity

⇒ Capacity (LPM) ⇒ Discharge Pressure (PSI) ⇒ Head Pressure (TDH) ⇒ Inlet Pressure (PSI) (Where NPSHₐ ≥ NPSHᵣ) ⇒ Viscosity (cP) - Ambient Temperature, Process Temperature ⇒ Solid Size & Content

Horizontal and vertical runs are important factors when determining head. Friction loss is critical to determining head pressure. To properly size a pump, the size and type of all fittings, valves and equipment must be taken into consideration.

⇒ Tubing Size_____________ ⇒ Tubing Size____________ ⇒ Vertical Drop____________ ⇒ Vertical Rise____________ ⇒ Total Elbows____________ ⇒ Horizontal Run__________ ⇒ Total Tees______________ ⇒ Total Elbows____________ ⇒ Total Valves_____________ ⇒ Total Tees______________ ⇒ Total Valves_____________

Butterfly_______ Ball_______ Disk Check_______Other_____________

DTI’s application engineers are available to assist you with diagnostic sizing. A completed sizing sheet is paramount for correct pump selection. There are many pump applications; determining which pump is appropriate for your needs is critical. To ensure many years of successful processing, contact DTI Inc. to help size your pump today. |

认证:

- 3A/FDA/BPE

订购资讯:

- 最小订购量: Negotiable

- 自行开发商品